|

CNC Machine Tools

|

|

|

|

In recent years,

the demand for high-precision machining of complex-shaped workpieces has been growing in the filed

of miniature precision

electronic components manufacturing, such as miniaturized power wirewound resistors,

In recent years,

the demand for high-precision machining of complex-shaped workpieces has been growing in the filed

of miniature precision

electronic components manufacturing, such as miniaturized power wirewound resistors,

|

|

miniaturized current sense.In response to such

demand, AWwT has

successfully developed the various integrated machine tools such

as :

• Multi-axis ( 5

servo motor controlled ) automatic wire winding

machine to meet

ultra-thin resistance wire ( 0.000394" diameter ) automatic

winding requirements,

• Automatic SMD

components measuring - sorting - marking -

packaging handling

center to meet our power wirewound and power current sense

applications

|

|

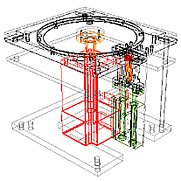

5-Axis

CNC automatic wire winding machine

|

|

|

In-house Design and

manufacture Multi-axis ( 5

servo motor axis ) Motion Controlled automatic wire winding machine,

design to meet auto winding the thinnest 0.010mm resistance wire winding

on a smallest ( 0.10mm diameter ceramic core,

The capability support

services of wire winding contract mfg. to our customers.

Applications:

In-house Design and

manufacture Multi-axis ( 5

servo motor axis ) Motion Controlled automatic wire winding machine,

design to meet auto winding the thinnest 0.010mm resistance wire winding

on a smallest ( 0.10mm diameter ceramic core,

The capability support

services of wire winding contract mfg. to our customers.

Applications:

|

|

Features :

• Advanced

Motion Control System

• Multi servo

motor axis designed to ensure delicacy handle of miniature parts

• Servo motor

controlled wire feed axis ensure precise control the thinnest

resistance wire feed and cut off.

• Vision

inspection unit

• Integration of

automatic measurement unit

• Full process

capability including marking and vision

• Compact machine

(main frame 800 x 600 mm)

Applications :

Custom

manufacturer of precision CNC machined components in prototype &

production quantities.

|

|

Numerical Control Automatic

Handler

|

|

In order to reach

0.001 ohm ultra-low resistance components' precision test and

post test process's marking, UV light harden, and packaging

demand, we designed 5GS0 series automatic handler, System

consist of multi-port measurement and monitor function,

In order to reach

0.001 ohm ultra-low resistance components' precision test and

post test process's marking, UV light harden, and packaging

demand, we designed 5GS0 series automatic handler, System

consist of multi-port measurement and monitor function,

|

|

Features :

• Very high speed

test handler dedicated to DISCRETE devices

• Equipped with

variable dimension bowl feeder

• Up to 3 test

stations plus 1 vision inspection station

• Rotary table

for marking unit integration

• Full process

capability including marking and vision

• Compact machine

(main frame 1283 x 895 mm)

Applications :

For high speed

precision SMD component test / sorting / marking / packaging

process integration

|

|